Manufacturing

Health and Safety

Manufacturing safely is very important in all technology workshops. The safe use of tools, machines, and equipment and following rules, signs and procedures will help prevent workshop accidents.

Safety rules are put in place to keep both you and others safe when in the workshop.

HEALTH AND SAFETY

TITLE:

*Tech Bitez *

*MUSIC *

ANIMATION SEQUENCE

Learning outcomes

STUDIO SEQUENCE

Joe and Sandy in workshop

JOE

Hello and welcome to the latest Tech Bitez.

On today's episode, we're talking about health and safety. Something I took very seriously in school. I was actually voted in as head safety officer of our class. Had my own Hi Vis, hard hat and safety glasses. Although I did find it strange, I was the only one who had to wear it in class. Sandy, there ' s nothing funny about safety.

JOE

Oh, I am so sorry, Joe, but I have a confession to make. There is no such thing as a safety officer in school. After numerous trips to A&E in first year. We had to do something, besides there's only so many times you can reattach the same finger. Plus, it means that you're perfectly placed to tell people what not to do in the workshop.

ANIMATION SEQUENCE

Animated section about health and safety in workshop.

JOE

As you are already kitted out. Let's start with the PPE. Personal protective equipment. The most common bits of PPE found in the workshop are, firstly, your safety glasses. These are very important and ensure that nothing can break off and hit you in the eye.

JOE

Been there, not fun, one star would avoid.

JOE

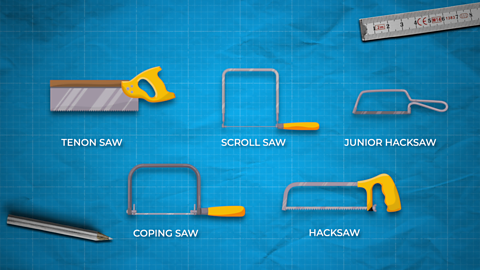

Next, we have our aprons. These not only keep your uniform clean, they also act as an extra protective layer between you and anything dangerous. They should be worn at all times when doing anything in the workshop. Tying back any loose hair, removing jewellery, and rolling up your sleeves is also advised. Certain machines in the workshop need some extra pieces of PPE. Here are some examples of these and the warning symbols that should accompany them. You should also only use a machine that you have been taught how to use safely, and even then, you should still be supervised. Only one person should be using a machine at any time. And of course, the safety guards and the machines should always be in place. Other hazards that can be found in the workshop will also have different warning symbols on or near them. Here are some examples that can be found around the workshop. These warning symbols will tell you about the hazardous material or machine that you are about to work with. You can then decide on what safety precautions you should take to mitigate any chance of injury. The final symbols that you should look out for in the workshop are these. If something does go wrong, knowing where the emergency stop buttons are is very important. You should also always know where the first aid and emergency eyewash stations are situated.

STUDIO SEQUENCE

Joe and Sandy in workshop

JOE

This one was always easy for me. They were just on my table. Hey, wait a minute.

Current safety signs

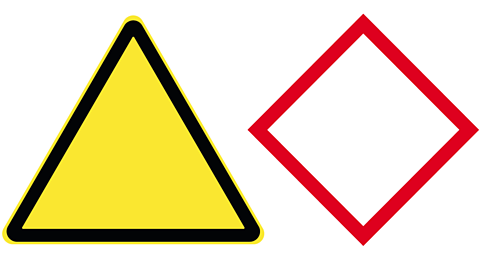

In the workshop there are many types of safety signs. These are split into four groups: Mandatory a sign prescribing specific behaviour (eg eye protection must be worn), Prohibition a sign prohibiting behaviour likely to increase or cause danger, Hazard alert us to the presence of a substance hazardous to health and Safe condition used to highlight safe routes or mark out safety facilities that can be accessed when necessary.

Sign

Type: Prohibition

Prohibition

Image caption, Meaning: What you must NOT do

Image caption, No naked flames

Image caption, Do not put fingers in machinery

1 of 3

Mandatory

Image caption, Meaning: What you MUST do

Image caption, You must wear ear protection

Image caption, You must wear eye protection

1 of 3

Hazard or danger warning

Image caption, Meaning: Warns of a risk or danger

Image caption, Danger - toxic or poison

Image caption, Warning - corrosive material

Image caption, Warning - electrical hazard

1 of 4

Condition

Image caption, Meaning: Safety facilities are nearby

Image caption, First Aid is here

Image caption, Emergency eye wash station

Image caption, Emergency stop button location

Note: The sign used for location of an emergency stop button is white on a red square.

1 of 4

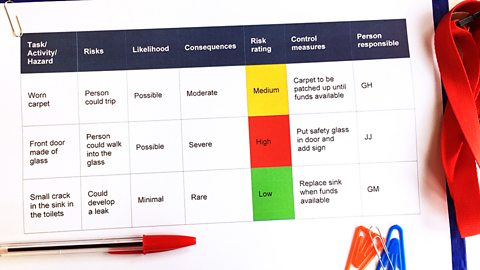

Risk assessments

What is a risk assessment and how it can be used.

A risk assessment is a careful examination of the things that could cause harm to people, and helps you to put precautions in place to prevent injury and ill-health.

A risk assessment consists of three sections – hazard, risk, and control measure.

Below shows a picture of what a typical risk assessment could look like.

How to assess risks

You must first identify any potential hazards This will be something that could hurt you or someone else, and its source. For example, a soldering iron could cause burns.

Secondly, you must state what the risk is. What is any possible way you could get hurt? In this example, it could be touching the tip of the soldering iron when moving it. Moving it would be the reason you or someone else would get burned.

Then, you must think of a control measure. This means asking yourself, how to avoid getting hurt? If the risk, like this example, is a risk of getting burned by a soldering iron, the control measure would be to allow the soldering iron to cool before attempting to move it.

Personal protective equipment (PPE)

How to Dress Safely in the Workshop

Personal protective equipment (PPE) must be worn when it is instructed to do so. Signs may be shown in the workshop showing you what items of protective equipment need to be worn when operating machines.

Examples of PPE

- protective gloves and aprons for working with heat

- goggles must be worn where there may be dust or splashing

- ear protection when using or working around noisy equipment

- dust mask when spray painting or wood

Test yourself

More on Manufacturing

Find out more by working through a topic

- count3 of 4

- count4 of 4

- count1 of 4